LYNCH BAR MANIFOLDS & ACCESSORIES

STANDARD SPECIFICATIONS

Standard Materials:

Aluminum-6061T6 and Ductile-654512

Other Material Options:

Mild Steel or Stainless Steel

Maximum Pressure:

Alu 3,000 PSI, Duc 5,000 PSI

Special Finishes:

Black Oxide, Electroless Nickel Plating, Anodizing

Mounting:

Required UNC or Metric mounting bolt kits and plugs supplied standard.

APPLICATIONS

Single Cylinder Presses - Subplates are needed when just one directional valve is required. They can include the relief valve of the system making it very compact and easy to setup.

Power Units - Additional features can easily be installed by using a subplate and connecting it to an existing Hydraulic Power Unit.

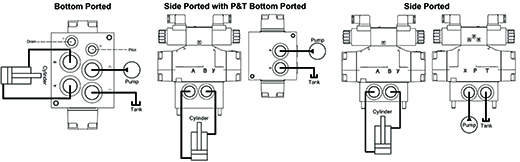

Subplates are also known as mounting pads, sub bases, and base plates. Subplates give valves a mounting pad, and allow for many different port styles and locations to meet the design requirements of the system. Subplates are designed to provide a means to connect a single solenoid valve to field piping either on the power unit or near the actuator. Subplates with Relief from P to T are designed to provide a means to connect a single solenoid valve to field piping either on the power unit or near the actuator. This manifold provides an integral system relief cavity to minimize piping. Our line of subplates are designed as a complete family with consistent mounting for all bottom ported, side/bottom ported, side ported & tank top designs.

FEATURES AND BENEFITS

- Port spacing has been maximized and aligned simplifying the installation of piping and minimizing space requirements.

- There is no variation in design layout for each Model, regardless of Port Code.

- All D05H and D05HE Subplates are designed with dual tank ports on the solenoid interface in order to maximize valve performance.

- Pilot ports and/or gauge ports are never on the same face as the work ports; a configuration which grants the user more space and convenience when assembling the hydraulic system.

- Clearance holes are located outside the solenoid valve interface limits wherever possible in order to facilitate valve assembly prior to mounting the subplate.

- Internal galleries have been maximized in order to minimize pressure drops and fluid velocities.

- Port spacing has been maximized and aligned simplifying the installation of piping and minimizing space requirements.

- No variation in design layout for each Model regardless of Port Code.

- Gauge Ports on Pressure Port are standard in order to facilitate the setting of the relief valve.

- "05T" Code provides dual tank ports without the pilot ports for D05H(E) designs for higher performance applications.

- "ST" Porting Style includes additional tank port on side in addition to bottom NPT tank port.

- Subplates with Circuits such as "P" Port Check With and Without Reliefs, Reducer on "P" Port and Cross-Line reliefs on "A" and "B" Ports are available. Please contact Factory for Part Numbers.

- Servo Subplates are available.

- Subplates for Gasket Mount Reliefs, Pressure Reducers, Flow Controls, etc. are available.

BLOCK DIAGRAM

BUILD A SUBPLATE

Type:

Type

Unselected

----

Material:

Material

Unselected

-

Valve Pattern:

Valve Pattern

Unselected

---

Porting Style

Porting Style

Unselected

--

Port Code:

Port Code

Unselected

--

Mounting Threads & Kit

Mounting Threads & Kit

Unselected

-

Relief Cavities and Pilot Port Options:

Pilot Port Options

Unselected

--

- SITE MAP

- PRODUCTS

- PARTNERS

NEWSLETTER